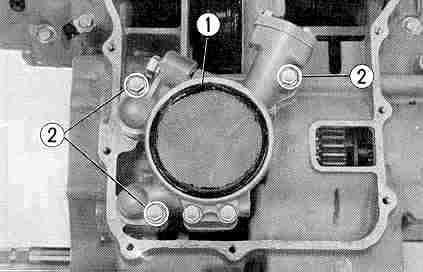

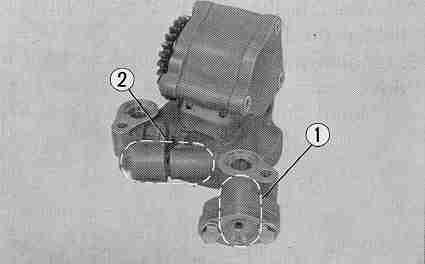

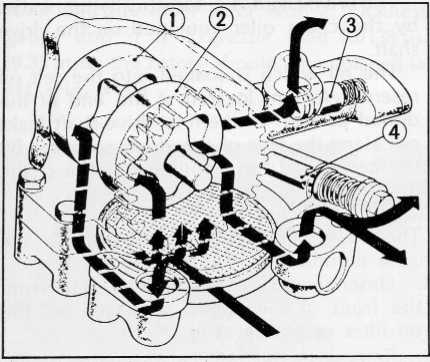

The oil pump is a rotor type trochoid pump mounted on the bottom of the crankcase and driven from the primary shaft through the kick gear. It consists of both the delivery and scavenge pumps, a leak stopper valve and a relief valve. (Fig. 3-4) (Oil leak stopper valve)

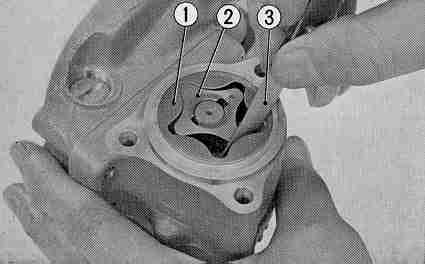

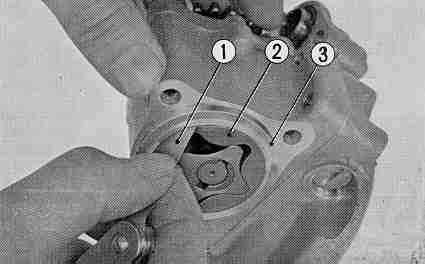

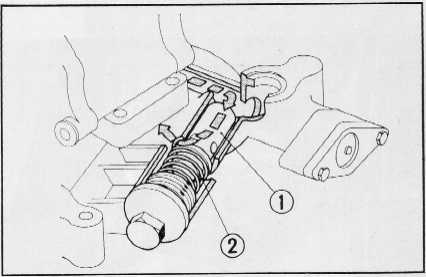

During engine operation, the oil pressure opens the oil leak stopper valve to maintain oil flow, and when the engine stops, the valve closes to prevent flow from the oil tank . (Fig. 3-5) (Relief valve)

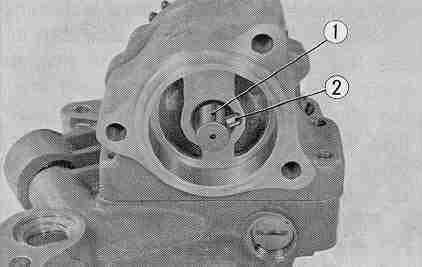

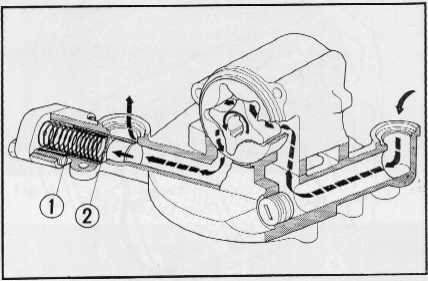

Relief valve is set at a specified pressure so that whenever the oil pressure exceeds this pressure, the valve opens and bypasses the oil to crankcase sump. In this way, the constant oil pressure is maintained.

This valve is incorporated in the delivery side of the oil pump. (Fig. 3-6)

Standard valve setting is 56.9lbs/in.2 (4.0+/-0.2 kg/cm2) at 4,000 rpm engine speed at oil temperature of 176'F (80'C).

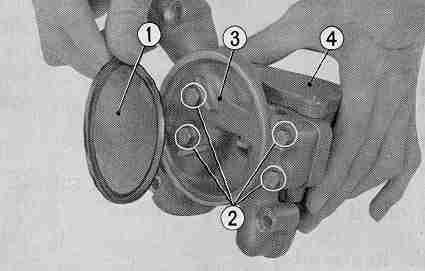

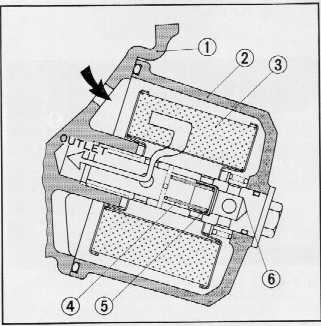

2. Oil filter

Oil filter is a full flow type using a replaceable element filter.

All the oil from the oil pump passes

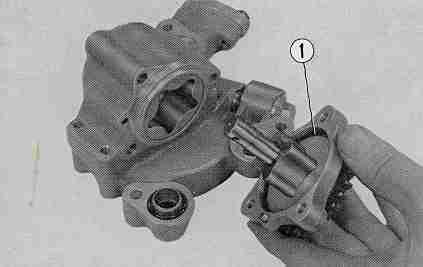

Fig. 3-4 (1) Delivery pump

(2) Scavenge pump

(3) Leak stopper valve

(4) Relief valve

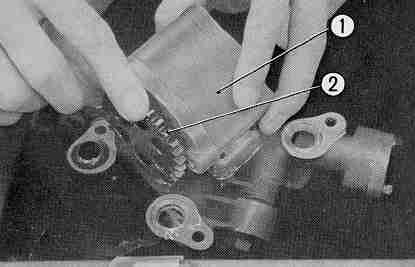

Fig. 3-5 (1) Oil leak stopper spring

(2) Oil leak stopper valve

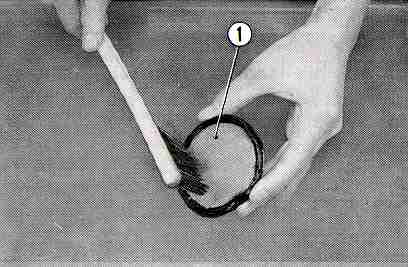

Fig. 3-6 (1) Relief valve

(2) Relief valve spring

Fig. 3-7 (1) Crankcase (4) By-pass valve

spring

(2) Oil filter case (5)By-pass valve

(3) Oil filter element (6)Center bolt