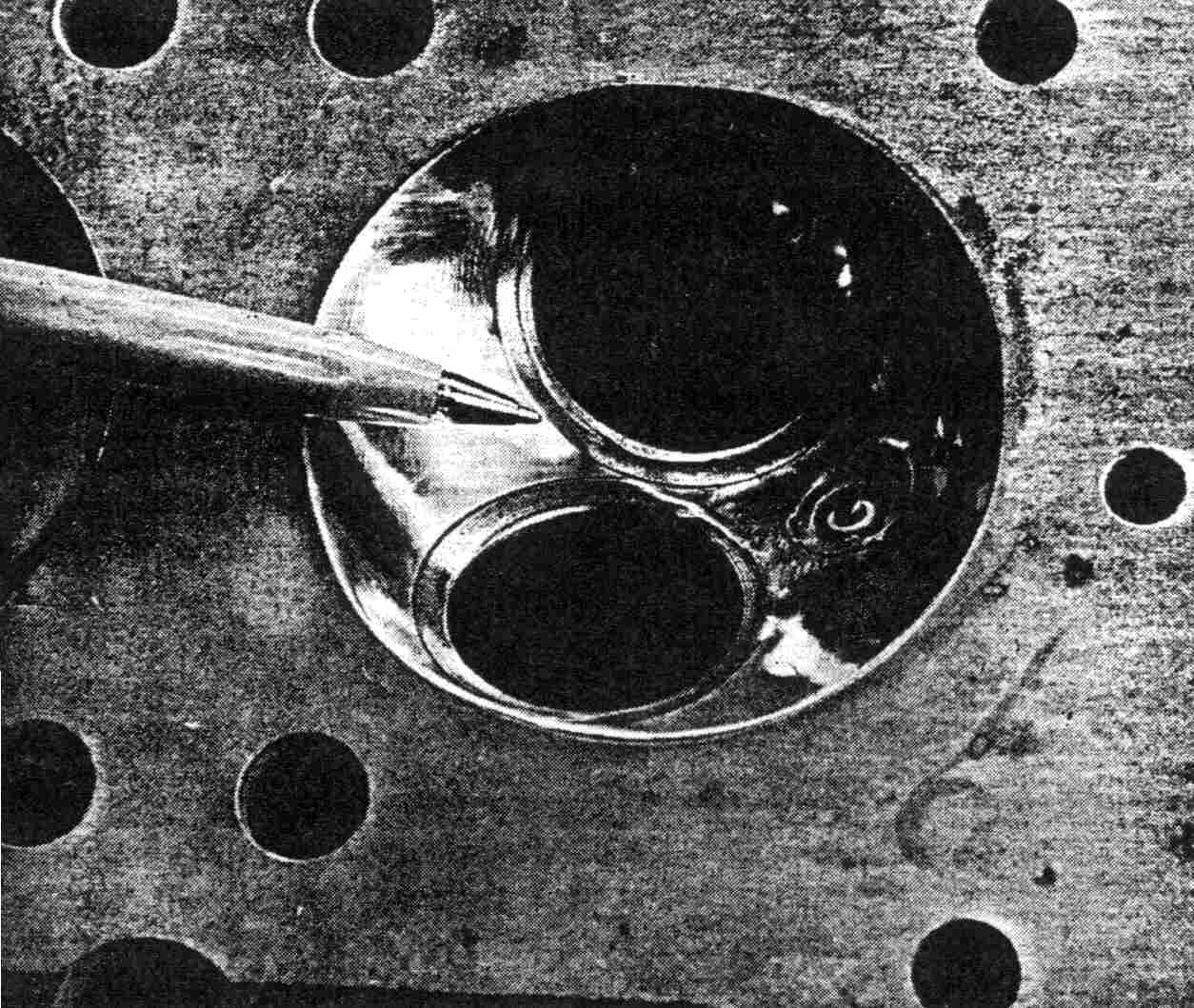

Jerry uses a tiny probe which can measure vacuum in different areas

of the port. By inserting the probe into the port, he can find those areas

which have less flow and can draw a graph of the flow deep inside the intake

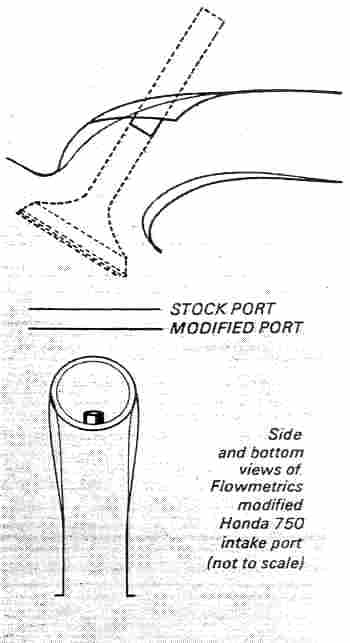

port. The first thing he found was that the majority of the air movement

was confined to the floor of the intake port. The valve guide area was

severely restricting the flow of air in the upper portion on the port and

would have to be reshaped to allow an increase in CFM. Also the height

of the guide projecting into the port should be cut down about 114-inch.

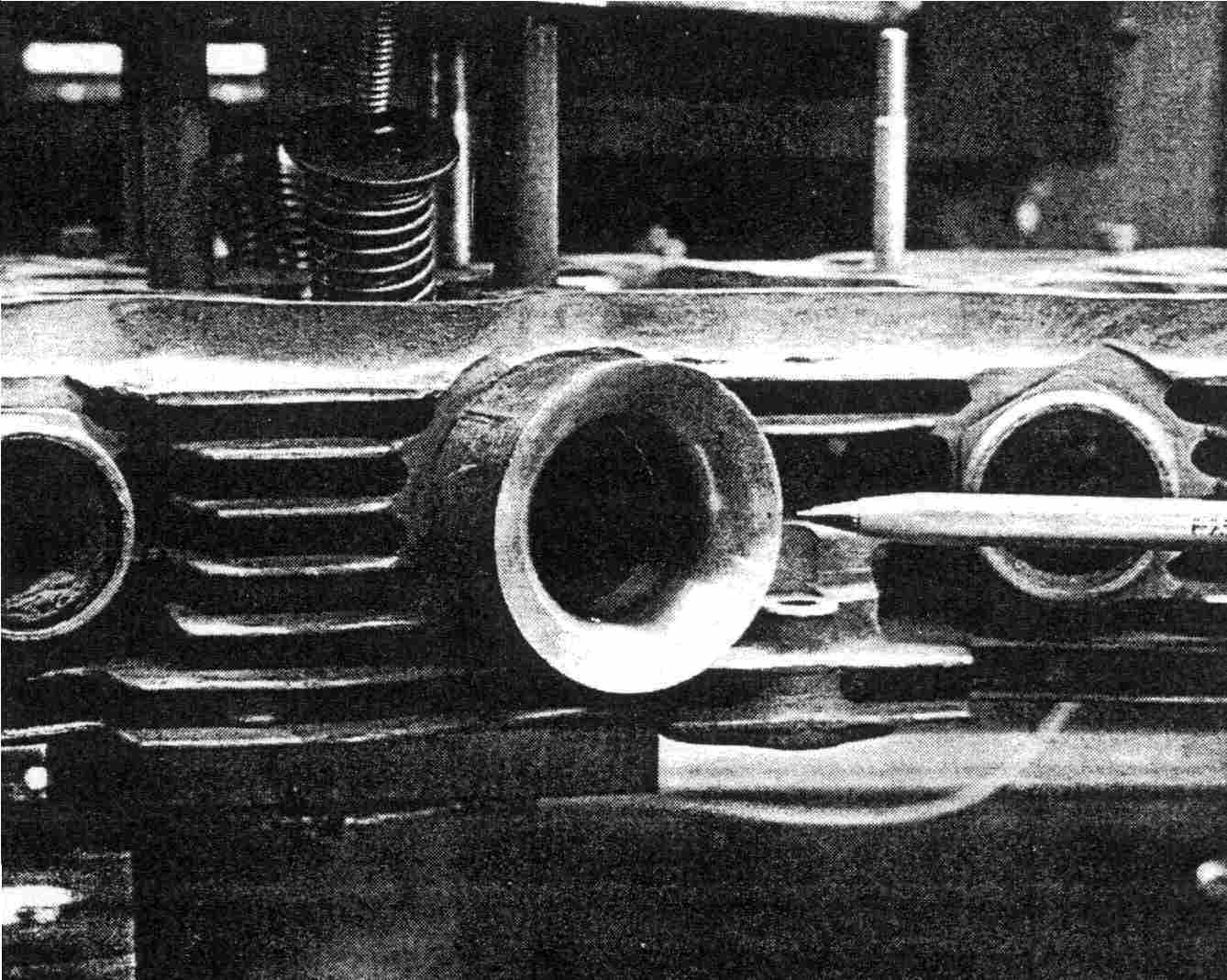

Reshaping the upper portion of the in- take port caused an increase in

the velocity of the flow which led us to the second discovery about the

port shape. The curve of the port directly behind the guide is too gradual

and forms turbulence, blocking part of the area around the valve head with

a disturbed wall of air. Jerry ground a deeper curve, almost a pocket behind

the guide and flow shot way up. Just the opposite condition exists on the

floor of the port. There the curve is tight and causes the air to try and

go around too much of an angle to reach the valve. The radius of the floor

was reduced slightly and the sides of the port just ahead of the valve

seat were opened up about 1/8-inch to form a mild venturi which would further

accelerate the air/fuel mixture into the chamber. After these modifications

had been made and the port polished smooth, Jerry removed most of the shrouding

in the combustion chamber, making the inside of the head look surprisingly

like a Chysler Hemi. The valve scat width was left stock.

Reinstalling the head on the flow bench, Jerry set up an open port

(entry only) test to sec what improvements had been made. The results were

astonishing! Flow in the open port was now 105.6-CFM, an open port increase

of 37 percent!

With the valve and 32mm Mikuni carburetor in place, flow was up

from 65.7-CFM at .350-inches lift to 73.3- CFM. The best part was that

the flow continued to increase rapidly all the way up to .450 lift, drawing

81.5-CFM. In this configuration, the Honda Four engine can make use of

a cam with really high lift, getting heavy charging of the cylinder, even

at rpm's above 10,000. On the basis of dyno testing on other small displacement,

multicylinder engines, Jerry believes that the required CFM for maximum

use of the air/fuel mixture would be in the area of 75-CFM. This means

that the modified Honda engine can be twisted to over 10,500 rpm without

running out of air! The final figure for the modified port and 32mm Mikuni

carburetor installation showed a 26.6-pereent increase in flow, a tremendous

gain for the small amount of reworking required.

The final test was with the stock Keihin carburetor on the modified

head. Flow was restricted slightly by the 28mm throat on the Keihin, but

at .450 lift the engine was still capable of pulling 72.4-CFM over the

original 58.7- CFM. Asked to estimate a horsepower increase on the ported

engine, Jerry said a 15-pereent increase was in the ball- park!

On the exhaust side of the chamber, very little need be done other

than polishing around the guide. This resulted in about a 10-pereent increase

in the area of the port just behind the guide. In normal practice, the

exhaust should be capable of flowing about 85-90 percent of the intake

rate. Jerry recommends that using straight pipes with megaphones, a flow

rate of 85 percent be maintained. Since the Honda exhaust port comes very

close to this in its stock state, very slight reworking is all that's necessary.

There you have it. If the extra power is wanted, it's available

with porting. Those of you running large displacement Honda Four engines

at the races would stand to gain the most from porting and polishing the

head The results speak for themselves! |